Intermittent bagmaker M250

A rugged powerhouse, the M250 is a high-performance vertical form fill and seal machine that offers the flexibility of open modular design- at an affordable price. The fast-action stepper jaw boasts 100 bags per minute. With bag dimensions of up to 250 mm wide (optional 400 mm bag width) by 400 mm long in a single stroke, plus a host of bag styles, the M250 is flexible, functional and economical. Like all our vffs machines, it has a linear actuator film web edge guide that aligns film with forming tube. Your result? An accuracy and user friendly machine which brings satisfation to your packaging needs!

max. 100 bags/min

max. 250 (350) × 400 mm

min. 50 x 60 mm

Machine description

A rugged powerhouse, the M250 is a high-performance vertical form fill and seal machine that offers the flexibility of open modular design- at an affordable price. The fast-action stepper jaw boasts 100 bags per minute. With bag dimensions of up to 250 mm wide (optional 400 mm bag width) by 400 mm long in a single stroke, plus a host of bag styles, the M250 is flexible, functional and economical. Like all our vffs machines, it has a linear actuator film web edge guide that aligns film with forming tube. Your result? An accuracy and user friendly machine which brings satisfation to your packaging needs!

Machine features

- Robust stainless steel frame

- Enclosed, direct drive jaw actuation

- Siemens or Allen Bradley control

- Off-the-shelf components

- Minimal maintenance requirements

- Short film path

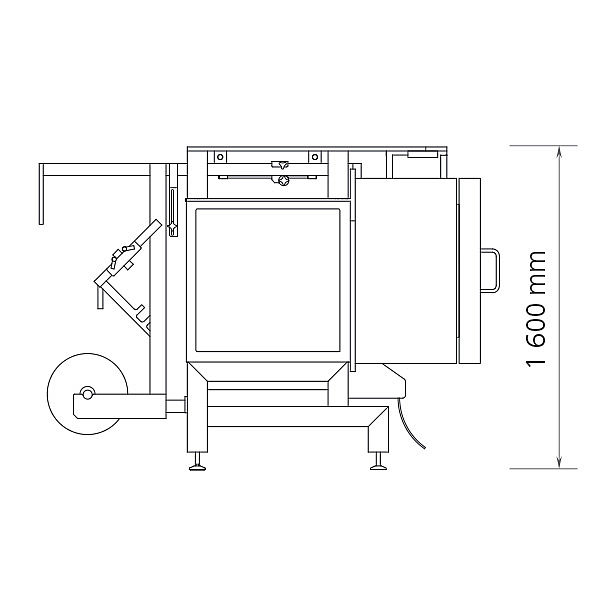

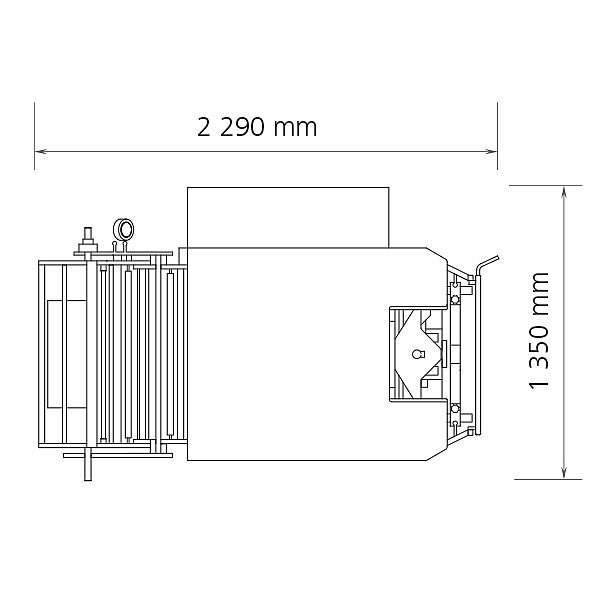

- Small machine footprint

- No tool change-over

- Self-centering pull belts

- Automatic film tracking

- VFD powered film unwind

- Quick film splice table

- Product stagers

- End-seal cooling air

- Bag deflators

- Photo eye and encoder

- Tri-fold guard door

- Jaw obstruction detection

- Runs most film structures

- Storage for 100 product recipes

Pillow

Pillow

Gussetted

Gussetted

Flat bottom

Flat bottom

Corner creased

Corner creased

Quad seal

Quad seal

True quad seal

True quad seal

Doy style

Doy style

Double doy

Double doy

Brick pack

Brick pack

Tetrahedron

Tetrahedron

3-side sealed

3-side sealed

Zip

Zip

Tin tie

Tin tie

Clip

Clip

Label

Label

Resealable tape

Resealable tape

Finger grip

Finger grip

Carry handle

Carry handle

Degassing valve

Degassing valve

Euroslot

Euroslot

Chain bag

Chain bag

- Quad seal bag assembly

- Flat bottom bag assembly

- Horizontal jaw for up to 340 mm (13.39") wide bag

- Impulse sealing for poly film structures

- Integration with variety of fillers, printers, metal detectors, label applicators, and checkweighers

- Washdown IP66 construction

- Vacuum pull belts

- Hole punch (Euroslot and Round)

- Load shelf

- Product settler

- Gas flush

- Static eliminator

- Tear notch

- Degassing valve applicator

- In-feed and take-away conveyors

- Remote diagnostics

- Zipper applicator

- Max. speed: 100

- Bag width: 60–250 mm

- Bag length: max. 400 mm (jeden potah)

- Weight: 750

- Power supply: 6

- Air pressure: 6

- Air consumption: 0,2

- Air consumption: 100

- Bag size max.: 250 (350) × 400

- Bag size min.: 50 x 60